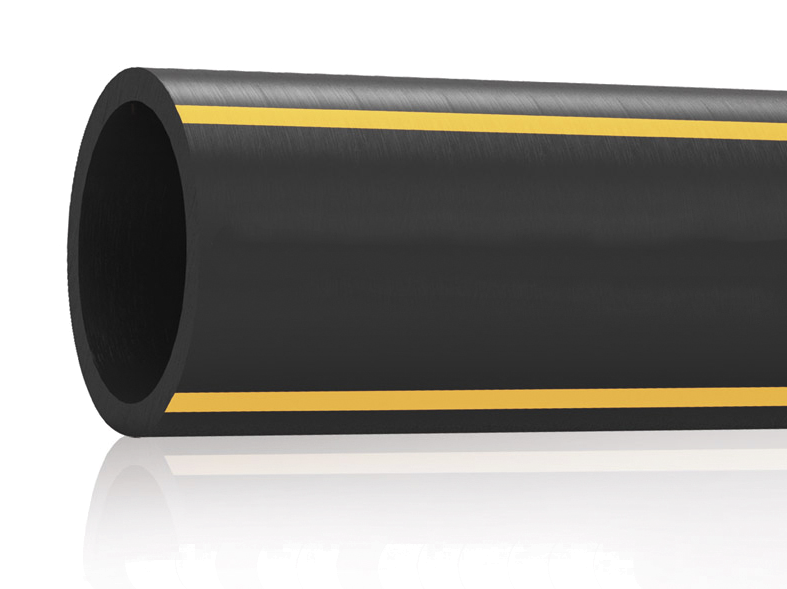

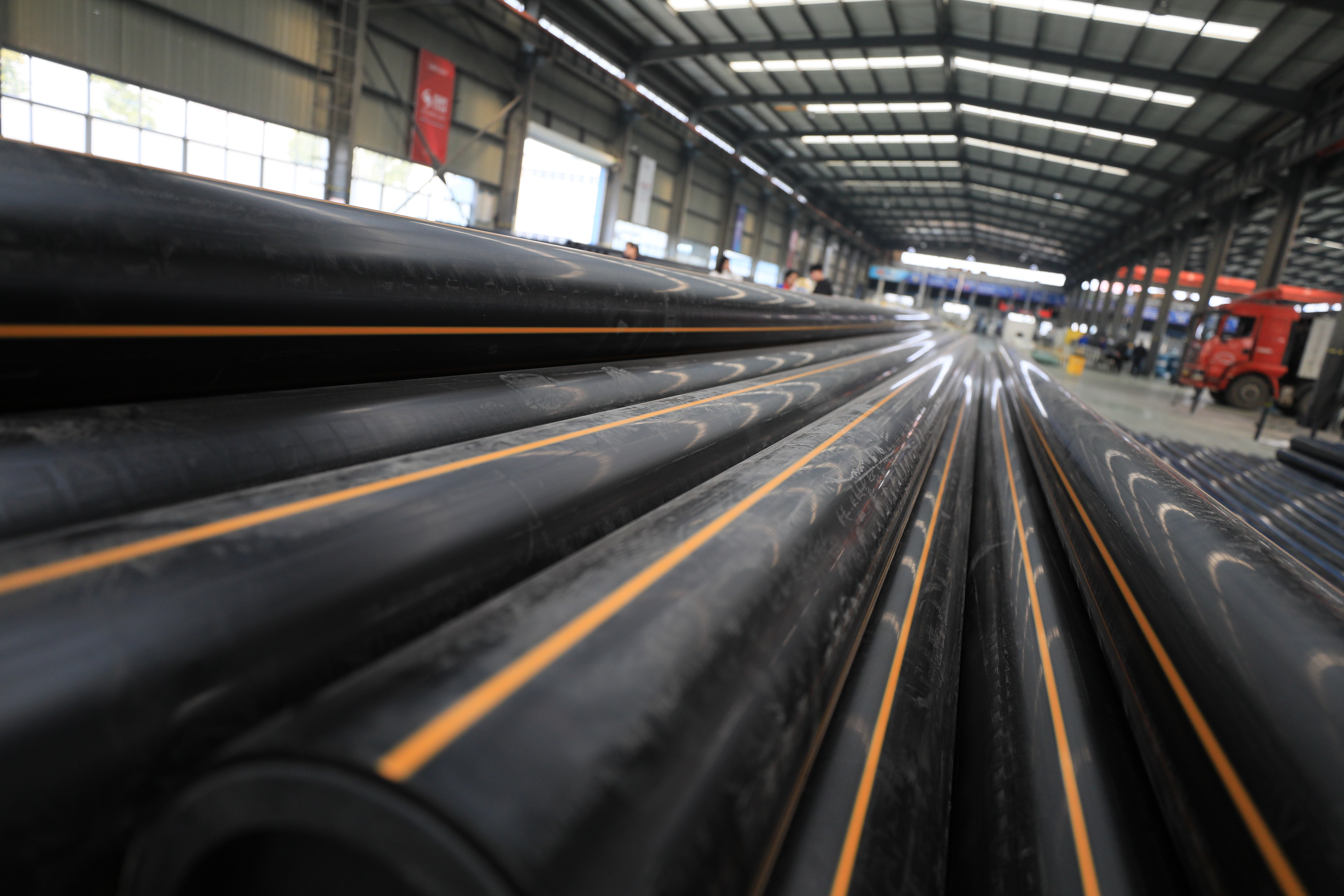

PE Pipe For Gas Supply

Marked with a yellow stripe, HDPE is an ideal, cost-effective and durable underground pipe for LPG and natural gas pipelines. It is cost effective, coming in long lengths to reduce the number of joins and enables the use of underground boring to speed up the installation process. Polyethylene piping is renowned world-wide for its ability to withstand even earthquakes, protecting vital infrastructure and reducing maintenance costs.

PERFORMANCE FEATURES:

- Corrosion resistance: Polyethylene (PE) is an inert materialthat resists corrosion of various chemical mediums. It is free from electrochemical corrosion and does not require a protective coating.

- Free from leakage: PE gas pipelines are mainly connected by electrofusion jointing which integrates the pipeline system. Compared with rubber seal joints, there is no risk of leakage caused by joint distortion.

- High toughness rating: PE gas pipe has a high toughness rating and the elongation at break point is generally above 500%. It has a strong adaptive and excellent anti-seismic capacity.

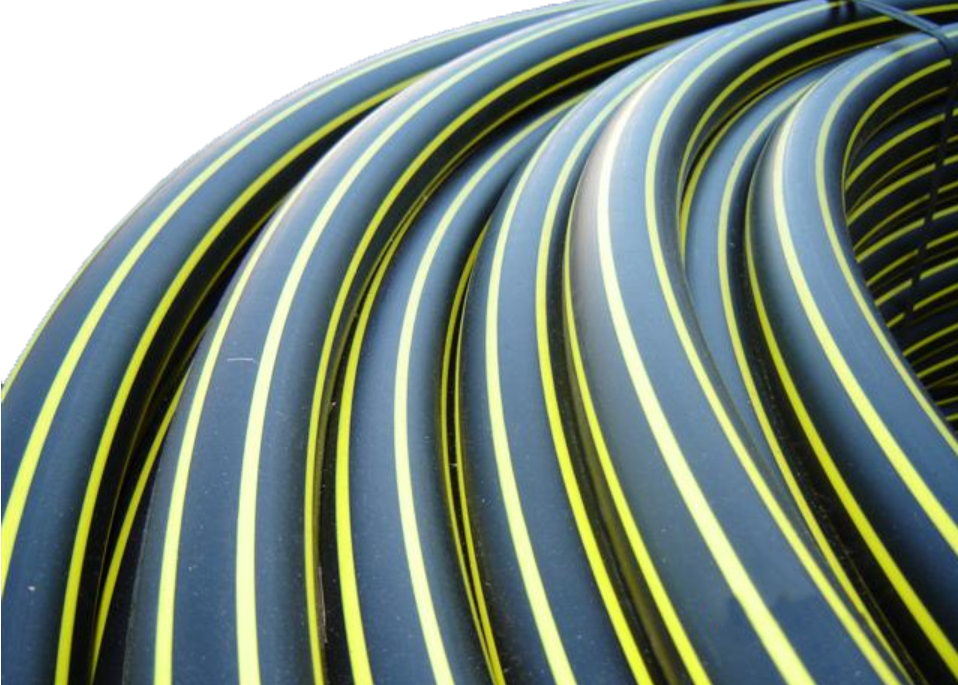

- Excellent Flexibility: Pipe diameters under 140mm may be reeled and provided in greater lengths to reduce the number of joints and pipe fittings. It may be used for trenchless installation as the direction of PE gas pipe can be changed easily according to the site requirements.

PN RATING:

≤ PN25

SPECIFICATIONS:

DN40 – DN1000

APPLICATIONS:

Gas supply of all capacity within every industry

螺旋波纹管材-80x80.png)